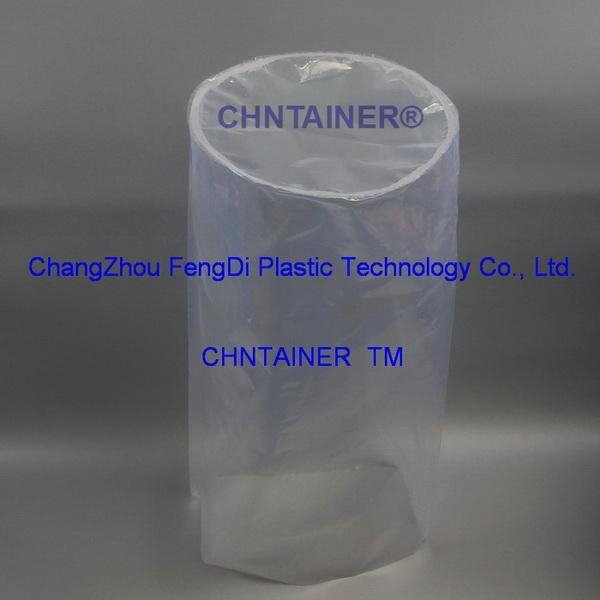

CHNTAINER® Heat-sealed Liner Pre-form-fit round bottom drum liners provide an economic solution for protecting your products. Pre-formed round bottom liners are ideal for use with viscous liquid,powder and particulate materials.

These liners are designed for easy installation and can be simply twisted and tied off to protect contents.

Special models are intended for use with solvents, flammable powders, hot liquids, oxygen-sensitive or hygroscopic materials or aggressive chemicals.

Typical Pre-Formed Round Bottom Drum Liner Markets:

Chemical (adhesives,chemicals,coatings,detergents,inks,paints,sealants)

Cosmetic (cleanser,liquid makeup,lotion,mascara,powder)

Food (caramel,chocolate,fruit,dairy)

Pharmaceutical

Key Benefits:

Pre-formed round bottom liners ensure the absolute purity of your product.

The round bottom shape allows maximum recovery of your valuable product, as it minimizes wrinkles and folds.

Round bottom liners reduce drum cleaning and reconditioning costs.

Environment-friendly packaging, helps users to reach sustainability goals.

Multiple Sizes:

Pre-Formed Round bottom liners are available in 12, 16, 30, 55 and 85 gallon sizes.(48L,64L,120L,220L,340L)